Frequently Asked Questions

D/F has now added a Frequently Asked Questions page to the website! This page will be continually updated and added to in hopes of fulfilling the needs of anyone who might have a common question about D/F's equipment or welding in general. Please visit the FAQ page here.

Here are the answers to a few frequently asked questions that can be found on the website:

How Do I Install a New Wire Casing/Conduit on a D/F Torch?

Remove the contact tip and any Allen screws or body screws. Remove the feeder adapter and casing/conduit from the torch and drive rolls, and slide the liner out. Attach a new casing/conduit to the torch and tighten the Allen screw against the casing/conduit. Properly measure and fit a new liner, sliding through the top of the casing/conduit. Replace the gas diffuse and contact tip, and tighten any remaining Allen or body screws to the Docking Spool or Inner Body.

Read more...

How Do I Cut, Fit, and Install a New Liner in a D/F Torch?

It is easiest to hold a new liner up to a used liner to cut for exact length. If this cannot be done, the new liner must be fitted properly. Remove the contact tip from the torch. Feed the new uncut liner through the feeder adapter and the conduit/casing, making sure the cables are free from twist. Cut the liner flush with the end of the copper gas nozzle. Remove the liner again and cut off the length of the tip plus the desired 1/8" or 3/8" set back. Now the liner has been properly sized. Replace the current tip, and then insert the new liner.

Read more...

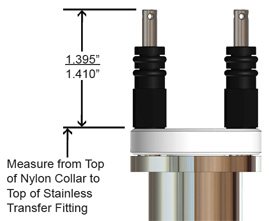

What is the Proper Way to Install a New Transfer Fitting (D/F #40025)?

Each D/F torch requires 2 Transfer Fittings. These parts are crucial to the water-cooling in the torch. The have to be set to a specific height range to provide effective water passage. Always use a long 3/8" socket for support when applying transfer fittings. Holding the water cooled nozzle in your hand, screw on the new transfer fitting. Place your index and middle fingers on the white collar as if throwing a fork ball, to hold the collar down tight. Measure from the top of the collar to the top of the stainless on the transfer fitting. In the factory, this height is set to 1.400", but an acceptable range is between 1.395" - 1.410". Make sure the O-rings are lubricated before placing the water-cooled nozzle back in the torch. Make sure the water-cooled nozzle is pushed up correctly and tightened with he cone nut. Read more... Each D/F torch requires 2 Transfer Fittings. These parts are crucial to the water-cooling in the torch. The have to be set to a specific height range to provide effective water passage. Always use a long 3/8" socket for support when applying transfer fittings. Holding the water cooled nozzle in your hand, screw on the new transfer fitting. Place your index and middle fingers on the white collar as if throwing a fork ball, to hold the collar down tight. Measure from the top of the collar to the top of the stainless on the transfer fitting. In the factory, this height is set to 1.400", but an acceptable range is between 1.395" - 1.410". Make sure the O-rings are lubricated before placing the water-cooled nozzle back in the torch. Make sure the water-cooled nozzle is pushed up correctly and tightened with he cone nut. Read more...

How Should I Set Up My Welding Environment?

Avoid environments with increased hazard of electric shock such as areas with physical constraints for the operator, areas with risk of contact with conductive elements, and wet or damp locations. Also ensure that the welding area is well ventilated. Read more...

Where Should I Locate My Power Supply?

Find an area free from moisture and dust. Find an area free from oil, steam, and corrosive gases. Locate an area not subjected to abnormal vibration or shock. Try to avoid direct sunlight or rain. Place the power supply at a distance of 1 ft. (30 cm) or more from the wall or from any similar object that could restrict natural air flow for cooling. Keep a minimum ground clearance of 5.5 in. (14 cm).

Read more...

How Should I Set My Drive Roll Pressure to Avoid Slippage?

The movable roller applies pressure to the grooved roller via screw adjustable spring pressure. The adjustable spring screw should be adjusted to a minimum pressure that will provide satisfactory wire feed without slippage. If slipping occurs, and inspection of the contact tip reveals no wear, distortion or bum-back jam, the conduit liner should be checked for kinks and clogging by metal flakes and swarf. If this is not the cause of slipping, the feed roll pressure can be increased by rotating the adjustable spring screw clockwise. The use of excessive pressure may cause rapid wear of the feed roller, motor shaft, and motor bearings. Please note that genuine D/F contact tips and liners should be used with D/F torches. Many non-genuine parts use inferior materials which can cause wire feed problems. Read more...

For more detailed answers to these questions, and for answers to many other frequently asked questions, visit the D/F FAQ page here.

|