|

Here is your most recent issue of High Current News. It's packed full of information to keep you updated with the latest MIG & TIG news, product information and updates from D/F MACHINE SPECIALTIES.

D/F is a world leader in the design, development, and manufacture of MIG & TIG welding products, consumables & accessories.

|

|

|

D/F will soon be releasing a brand new color product catalog! Featuring the most popular D/F MIG & TIG welding equipment, accessories and consumables, the catalog will cater to your informational and ordering needs. D/F will soon be releasing a brand new color product catalog! Featuring the most popular D/F MIG & TIG welding equipment, accessories and consumables, the catalog will cater to your informational and ordering needs.

You can reserve your own free copy of the catalog in two ways:

1. Email D/F at sales@dfmachinespecialties.com with your name, and your company's name and address of where you would like the catalog to be sent.

2. Fill out the reservation form located here.

If you would like a digital copy of the catalog, please visit the D/F catalog downloads page here.

|

D/F Machine Specialties will showcase several new heavy-duty automated and robotic MIG & TIG welding products at the FABTECH 2012 Welding Show in Las Vegas, NV at the Las Vegas Convention Center November 12-14. Look for D/F in booth #N2224.

D/F now offers its torches, parts and accessories as CAD file downloads. The models are created with SolidWorks, but D/F provides several universal file formats for download to accommodate a wide variety of different software platforms. Check out the CAD File Downloads page here.

|

Pushing Aluminum Wire - Improving Weld Quality

Aluminum was the original wire type associated with MIG welding and remains a popular choice today. Along with the prevention of weld metal porosity (explained in High Current News Volume 4, Dec. 2010), proper travel of aluminum wire through the utilities and the torch is essential for clean, consistent welds, and can also reduce a few costs.

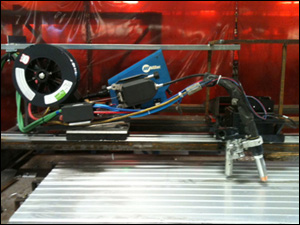

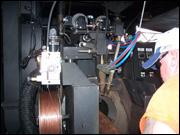

Just recently the engineers at D/F were able to make a tremendous difference in the quality of the aluminum welds for a customer by suggesting a few simple adjustments to their setup. These changes can be seen in the Before and After pictures below. The customer is welding 50 ft. trailer beds with 3/64" aluminum.

First, there was an opportunity for the torch to be moved much closer to the wire feeder, about 3 feet closer in this case. The less distance the wire has to travel, the less chance for the wire to lose its straightness. Turning the wire feeder 90° toward the torch also helped reduce this distance.

Next, the point at which the wire left the spool was put inline with the wire feeder so that there was no bend prior to entering the wire drive.

These changes also reduced overall bend of the utilities to just a single simple radius into the torch resulting in a tighter, cleaner, more compact overall setup. Along with better wire travel, the customer will see increased contact tip life due to a straighter wire exit (less friction on the tip), and also see reduced cost for replacement utilities as their length has been cut by more than half.

Before

|

|

|

After

|

|

|

Do You Have Photos of Projects? Submit Them to WIN!

D/F's new Photo Gallery showcases D/F equipment in action over the years, and we are constantly adding to the gallery. We want to see how our equipment helps brings out the best of your creativity and skill, or simply how your equipment is setup and used.

Submit your photos and projects to:

Newsletter@DFMachineSpecialties.com

For project submissions, things to include:

-

Photos of your project

-

What did you make?

-

How did you make it?

-

Which D/F products did you use?

Project submissions will be put in a drawing for a chance to Win A Gift Card to your local Best Buy Consumer Electronics Store.

Check out the D/F Photo Gallery here.

|

|

Words from the Editor

Greetings from D/F!

Thank you for reading our High Current News e-newsletter. Please share this issue with a friend and send us your comments.

Enjoy!

Best Regards,

Dave Judd, Editor

D/F Machine Specialties, Inc.

|

|

In This Issue

-

New D/F Product Catalog

-

Frequently Asked Questions

-

Got Projects? Submit to WIN!

-

New Products

|

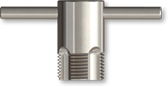

New Products - Nozzle Thread Chaser Taps

The New D/F Nozzle Thread Chaser Taps are designed to chase and tap nozzle threads to clean and repair them for better conductivity and contact.

-

Chasing will clear debris, metal filings and spatter

-

Re-tapping will straighten and clean damaged threads

-

Tap sizes available for all D/F Nozzle Assemblies

Read More

|

Your Downloads

Did you know you can download all of D/F's Catalogs, Forms, Instruction Manuals and CAD Files at D/F's Online Download Center?

|

Contact D/F

Product Info: 1-507-625-6200

Fax: 1-507-625-6203

Online: Contact D/F

D/F Machine Specialties, Inc.

1750 Howard Drive

North Mankato, MN 56003

|

|

Follow D/F

You can interact with D/F on Facebook, MySpace, Twitter, Flickr, and YouTube. Sign up to become a Fan on our Facebook Fan Page, become our friend on MySpace, follow us on Twitter, check out high quality photos of our products on Flickr, and see our latest videos on YouTube!

|

|