|

Here is your most recent issue of High Current News. It's packed full of information to keep you updated with the latest MIG & TIG news, product information and updates from D/F MACHINE SPECIALTIES.

D/F is a world leader in the design, development, and manufacture of MIG & TIG welding products, consumables & accessories.

|

|

D/F Machine Specialties will showcase several new heavy-duty automated and robotic MIG & TIG welding products at FABTECH 2012 Welding Show in Las Vegas, NV at the Las Vegas Convention Center November 12-14. Look for D/F in booth #N2224. D/F Machine Specialties will showcase several new heavy-duty automated and robotic MIG & TIG welding products at FABTECH 2012 Welding Show in Las Vegas, NV at the Las Vegas Convention Center November 12-14. Look for D/F in booth #N2224.

|

|

D/F Machine Specialties, Inc. will be closed November 22 & 23, 2012 for Thanksgiving. We will also be closed December 24th, 2012 through January 1st, 2013 for our Holiday shutdown. Please plan your product needs to reflect this shutdown. Let us take this time to extend our sincere appreciation for your friendship, good will, and loyalty, wishing you a Happy Holiday and a Successful New Year! D/F Machine Specialties, Inc. will be closed November 22 & 23, 2012 for Thanksgiving. We will also be closed December 24th, 2012 through January 1st, 2013 for our Holiday shutdown. Please plan your product needs to reflect this shutdown. Let us take this time to extend our sincere appreciation for your friendship, good will, and loyalty, wishing you a Happy Holiday and a Successful New Year!

|

|

|

D/F has released a brand new color product catalog! Featuring the most popular D/F MIG & TIG welding equipment, accessories and consumables, the catalog will cater to your informational and ordering needs. D/F has released a brand new color product catalog! Featuring the most popular D/F MIG & TIG welding equipment, accessories and consumables, the catalog will cater to your informational and ordering needs.

You can request your own free copy of the catalog in two ways:

1. Email D/F at sales@dfmachinespecialties.com with your name, and your company's name and address of where you would like the catalog to be sent.

2. Fill out the reservation form located here.

Click to download the catalog in digital form as a PDF. Click to download the catalog in digital form as a PDF.

|

|

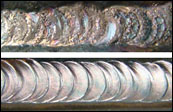

Welding with Clean Aluminum Wire and Base Metal

Aluminum is a very common choice for wire and base metal when determining a MIG welding job. The better job you do of cleaning the wire and base metal before you start welding, the better the result will be. It can be the difference between a bad weld (top image) and a clean, consistent and attractive weld (bottom image). Aluminum is a very common choice for wire and base metal when determining a MIG welding job. The better job you do of cleaning the wire and base metal before you start welding, the better the result will be. It can be the difference between a bad weld (top image) and a clean, consistent and attractive weld (bottom image).

Preparing Base Metal

Cleaning the base metal prior to welding is important for achieving clean, consistent welds. There are a few tips to keep in mind when preparing the base metal:

1. Use acetone or another organic solvent to remove oil and grease from the weld surface. Wipe it with clean water to remove any residue, and let it dry completely.

2. Use a stainless steel wire brush (one that is only used for aluminum work) to remove surface oxides. Only brush in one direction, and only do this after the metal has been cleaned with an organic solvent.

3. If the metal will sit for a period of time before welding, cover the metal so that no new contaminants may make contact.

4. Keep the aluminum dry and at room temperature.

5. Complete the job within a few days to avoid aluminum oxide reforming. If this is not possible, be sure that the metal is cleaned again before you continue.

Preparing Aluminum Wire

Clean aluminum wire is just as important as clean base metal. Several tips above can be considered when preparing the welding wire. Also consider these tips for optimum wire performance:

1. Store the aluminum wire spool in a clean place when not in use. Cover it to prevent coming in contact with dust and debris.

2. Keep the aluminum wire running as straight as possible through the torch assembly and utility lines. Friction can cause inner torch parts to wear and the wire could collect any of the resulting debris.

If you have any questions about welding with aluminum, please do not hesitate to contact the factory.

Phone: (507) 625-6200 · Email: sales@dfmachinespecialties.com Phone: (507) 625-6200 · Email: sales@dfmachinespecialties.com

We look forward to helping you with your aluminum welding applications!

|

|

Frequently Asked Questions

D/F has now added a Frequently Asked Questions page to the website! This page will be continually updated and added to in hopes of fulfilling the needs of anyone who might have a common question about D/F's equipment or welding in general. Please visit the FAQ page here.

|

|

Do You Have Photos of Projects? Submit Them to WIN!

D/F's new Photo Gallery showcases D/F equipment in action over the years, and we are constantly adding to the gallery. We want to see how our equipment helps brings out the best of your creativity and skill, or simply how your equipment is setup and used.

Submit your photos and projects to:

Newsletter@DFMachineSpecialties.com

For project submissions, things to include:

-

Photos of your project

-

What did you make?

-

How did you make it?

-

Which D/F products did you use?

Project submissions will be put in a drawing for a chance to Win A Gift Card to your local Best Buy Consumer Electronics Store.

Check out the D/F Photo Gallery here.

|

|

Words from the Editor

Greetings from D/F!

Thank you for reading our High Current News e-newsletter. Please share this issue with a friend and send us your comments.

Enjoy!

Best Regards,

Dave Judd, Editor

D/F Machine Specialties, Inc.

|

|

|

In This Issue

• Fabtech Vegas 2012

• D/F Holiday Shutdown

• New D/F Product Catalog

• Clean Aluminum Welding

• Frequently Asked Questions

• Got Projects? Submit to WIN!

• New Products

|

New Products - Curved Robotic Torches

The versatile D/F curved quick-change Water-Cooled Robotic 500 amp Torch Models NCC/LRN and HTC/LRN can be used for a wide range of robotic applications. With the various angles (22° through 90°) and lengths available, a selection may be made to suit individual requirements. The composite modular design of the rugged, yet flexible quick-disconnect Model LRN (Long Reach Nozzle) torches allow the user to quickly change the goose-neck or cable assembly while maintaining tool center point, assuring accurate repeatability and continuous precision welding.

Read More

|

Your Downloads

Did you know you can download all of D/F's Catalogs, Instruction Manuals and CAD Files at D/F's Online Download Center?

|

Contact D/F

Product Info: 1-507-625-6200

Fax: 1-507-625-6203

Online: Contact D/F

D/F Machine Specialties, Inc.

1750 Howard Drive

North Mankato, MN 56003

|

|

Follow D/F

You can interact with D/F on Facebook, MySpace, Twitter, Flickr, and YouTube. Sign up to become a Fan on our Facebook Fan Page, become our friend on MySpace, follow us on Twitter, check out high quality photos of our products on Flickr, and see our latest videos on YouTube!

|

|

|

|

|

|

|

|

|