|

Here is your most recent issue of High Current News. It's packed full of information to keep you updated with the latest MIG & TIG news, product information and updates from D/F MACHINE SPECIALTIES.

D/F MACHINE SPECIALTIES, family owned and operated since 1966, is a world leader in the design, development, and manufacture of American made MIG (GMAW) & TIG (GTAW) welding products, consumables and accessories for robotic and welding automation equipment.

|

|

|

D/F has released a brand new color product catalog! Featuring the most popular D/F MIG & TIG welding equipment, accessories and consumables, the catalog will cater to your informational and ordering needs. D/F has released a brand new color product catalog! Featuring the most popular D/F MIG & TIG welding equipment, accessories and consumables, the catalog will cater to your informational and ordering needs.

You can request your own free copy of the catalog in two ways:

1. Email D/F at sales@dfmachinespecialties.com with your name, and your company's name and address of where you would like the catalog to be sent.

2. Fill out the reservation form located here  . .

Click to download the catalog in digital form as a PDF. Click to download the catalog in digital form as a PDF.

|

|

Dealing with Wire Burnback

In welding, burnback occurs when wire continues to burn away from the weld pool back towards the contact tip after the weld has been completed. Sometimes burnback can be desired when trying to offset the inertia of the drive roll stand, or to leave the end of the wire crisp and ready for the next weld job. On the other hand, burnback can leave you with a number of problems, and its particular cause can be somewhat difficult to track down. In welding, burnback occurs when wire continues to burn away from the weld pool back towards the contact tip after the weld has been completed. Sometimes burnback can be desired when trying to offset the inertia of the drive roll stand, or to leave the end of the wire crisp and ready for the next weld job. On the other hand, burnback can leave you with a number of problems, and its particular cause can be somewhat difficult to track down.

When burnback is desired it can be considered the final step in making a weld. At this point the filler wire will be separated from the weld puddle and the arc will be terminated. Many systems have a control setting for burn back that, when used properly, will do a nice job of cutting the weld off and leaving the wire ready for the next job with no ball of metal on the end of the wire.

In many cases, burnback can leave undesired results and poor ending conditions. When a weld ends poorly, it leaves the next weld a lot to be desired. It can lead to failed arc starts, or if the wire burns back too far it can weld the wire right to the contact tip itself, and the fused contact tip would have to be removed. Dealing with fused burnbacks on threaded tips versus slip-in tips can really result in a difference in cost and downtime.

HTM or Threaded Tips

A burnback with a threaded tip will result in trouble, downtime and wasted wire. When removing a threaded tip with a burnback, the weld engineer would have to go 15 ft. to the back of the machine and cut the wire, then return to the front of the torch and remove the tip, resulting in 15 ft. of wasted wire. Alternatively, the tip could be cut in half if a hacksaw is handy in the weld shop. In any case of burnback, the contact tip will have to be replaced. The new wire can then be fed through the torch, a new tip inserted, the desired stickout cut off, and the weld process restarted.

NCM or Slip-In Tips

A burnback with a slip-in tip provides much less trouble and waste. When removing a slip-in tip with a burnback, the collet can simply be loosened 1/4 to 1/2 turn, the wire jogged out and 3 inches removed, a new tip inserted, and the weld process can then be restarted. In this case you will lose much less wire, cause much less downtime, and the loss of a slip-in tip is relatively inexpensive compared to a threaded tip.

If you have any questions about fine tuning or avoiding burnbacks, or dealing with burnbacks on slip-in or threaded tips, please do not hesitate to contact the factory.

Phone: (507) 625-6200 · Email: sales@dfmachinespecialties.com Phone: (507) 625-6200 · Email: sales@dfmachinespecialties.com

We look forward to helping you with your welding applications!

|

|

NEW Video: D/F Air-Cooled MAC-5 Barrel on BUG-O CWE-5

Check out the D/F Machine Specialties Model MAC-5 Part Number 17811 Air-Cooled Barrel welding 3/64" Aluminum on the BUG-O Systems CWE-5. This is an aluminum package that was put together by Airgas process specialists. The CW-5 Circle Welder with Remote Control is designed for single or multi-pass welding of couplings or nozzles on pipe and vessels utilizing MIG or Flux Core process, with gas shield. The machine is equipped with its own wire feeder, rotation drive motor, rise and fall cam assembly and welding gun. Horizontal and vertical racking to position the torch and a 30 lb (14 kg) spool holder. OTC Daihen is providing the DP400 power source and CMRE-741 4-roll wire feeder.

|

|

Frequently Asked Questions

D/F has now added a Frequently Asked Questions page to the website! This page will be continually updated and added to in hopes of fulfilling the needs of anyone who might have a common question about D/F's equipment or welding in general. Please visit the FAQ page here.

|

|

Do You Have Photos of Projects? Submit Them to WIN!

D/F's new Photo Gallery showcases D/F equipment in action over the years, and we are constantly adding to the gallery. We want to see how our equipment helps brings out the best of your creativity and skill, or simply how your equipment is setup and used.

Submit your photos and projects to:

Newsletter@DFMachineSpecialties.com

For project submissions, things to include:

-

Photos of your project

-

What did you make?

-

How did you make it?

-

Which D/F products did you use?

Project submissions will be put in a drawing for a chance to Win A Gift Card to your local Best Buy Consumer Electronics Store.

Check out the D/F Photo Gallery here  . .

|

|

Quick-Click Buttons

The following are buttons that link you directly to the D/F website. Just click on the icon below for the desired item.

|

Words from the Editor

Greetings from D/F!

Thank you for reading our High Current News e-newsletter. Please share this issue with a friend and send us your comments.

Enjoy!

Best Regards,

Dave Judd, Editor

D/F Machine Specialties, Inc.

|

|

|

|

|

In This Issue

• NEW D/F Product Catalog

• Dealing with Wire Burnback

• NEW Product Video - BUG-O,

OTC, D/F, Welding 3/64" AL

• Frequently Asked Questions

• Got Projects? Submit to WIN!

• New Products

• Nozzle Thread Chaser Taps

|

New Products - Automatic Curved Machine Torches

The versatile D/F curved quick-change Water-Cooled Automatic 500 amp Torch Models NCC/LRN and HTC/LRN can be used for a wide range of automatic applications. With the various angles (22° through 90°) and lengths available, a selection may be made to suit individual requirements. The composite modular design of the rugged, yet versatile quick-disconnect Model LRN (Long Reach Nozzle) torches allow the user to quickly change the goose-neck or cable assembly while maintaining tool center point, assuring accurate repeatability and continuous precision welding.

Read More

|

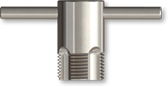

Nozzle Thread Chaser Taps

The New D/F Nozzle Thread Chaser Taps are designed to chase and tap nozzle threads to clean and repair them for better conductivity and contact.

• Chasing will clear debris,

metal filings and spatter

• Re-tapping will straighten and

clean damaged threads

• Tap sizes available for all D/F

Nozzle Assemblies

Read More

|

Your Downloads

Did you know you can download all of D/F's Catalogs, Instruction Manuals and CAD Files at D/F's Online Download Center?

|

Contact D/F

Product Info: 1-507-625-6200

Fax: 1-507-625-6203

Online: Contact D/F

D/F Machine Specialties, Inc.

1750 Howard Drive

North Mankato, MN 56003

|

|

|

|

|

|

|

|

|