Here is your most recent issue of High Current News. It's packed full of information to keep you updated with the latest MIG & TIG news, product information and updates from D/F MACHINE SPECIALTIES.

D/F is a world leader in the design, development, and manufacture of MIG & TIG welding products, consumables & accessories.

|

|

The Advantage of Preheat

Welding holds some of the most violent changes of temperature in the manufacturing industry. Pre-heating the metal can help prevent weld cracking caused by these extremities. Welding holds some of the most violent changes of temperature in the manufacturing industry. Pre-heating the metal can help prevent weld cracking caused by these extremities.

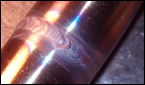

One of the main reasons for weld cracking has to do with the properties of the metal, which change during the welding process. As the weld cools, the steel undergoes multiple phases with different molecular structures, depending on the rate of cooling. If the steel cools too fast it can result in the formation of a hard and brittle structure called martensite. This structure can easily allow for weak welds and cracking. As the picture shows, the structure is formed in the adjacent base metal, and not so much in the weld metal, so the base metal is where the cracks will form.

Preheating the entire base metal, or even the base metal local to the weld, will help prevent cracking. The more area around the weld that is preheated, the longer it will take the weld to cool down, just because there is more material that needs to release heat. Preheating is very important for controlling the cooling rate of the weld area.

Check out D/F's 600°+ Preheat Torches

|

|

D/F Sneezer Anti-Spatter Gas Purge System

The D/F Sneezer Anti-Spatter Gas Purge System will reduce and help prevent spatter and buildup in the gas nozzle and minimize the need for nozzle cleaning. Anti-spatter mist injected through the gas ports in the gas diffuser coats the inside of the nozzle to prevent spatter build-up. Instead of cleaning after six or seven parts, numerous parts can be welded before cleaning is needed. The D/F Sneezer Anti-Spatter Gas Purge System will reduce and help prevent spatter and buildup in the gas nozzle and minimize the need for nozzle cleaning. Anti-spatter mist injected through the gas ports in the gas diffuser coats the inside of the nozzle to prevent spatter build-up. Instead of cleaning after six or seven parts, numerous parts can be welded before cleaning is needed.

The D/F Sneezer can be installed in any D/F MIG torch and incorporates a Mist Purge hose and cable assembly into your existing gas hose.

-

Reduce & help prevent spatter

-

Less down time due to cleaning

-

Fits any D/F MIG Gas Hose

Learn More About the D/F Sneezer

|

|

D/F Welding Tips & Tricks - Stainless Steel Repair with TIG

High quality stainless steel field repair requires knowledge and preparation for the complex metallurgical aspects of alloying. TIG is the ideal process in this situation due to its high control over the heat and weld pool size, and even for its portability. Below are a few specific tips for success this process. High quality stainless steel field repair requires knowledge and preparation for the complex metallurgical aspects of alloying. TIG is the ideal process in this situation due to its high control over the heat and weld pool size, and even for its portability. Below are a few specific tips for success this process.

-

Stainless alloys have relatively poor thermal conductivity, and too much heat can damage a weld. Color will indicate a correct amount of heat (straw/wheat shade to blue) or an excessive amount (grayish).

-

The TIG process allows for very small equipment configurations for hard to reach positions. Further, using a clear gas cup will help improve the visibility of the weld during the process.

-

Be careful with welds reaching a temperature over 800°F. If this weld is maintained for too long, protective chromium could be lost to chromium carbide formation and corrosion could result.

-

Since stainless has relatively poor thermal conductivity and high thermal expansion, the components of the weldment can be fixed in place to help prevent warping.

If you have any questions about Stainless Repair with TIG, do not hesitate to contact D/F and talk to an engineer who will help you with your concerns.

Check out D/F's Automatic & Robotic TIG Torches  . .

|

|

Got Projects? Submit Them to WIN!

We want to see how our equipment helps brings out the best of your creativity, skill, or whatever else helps you with your welding projects.

Submit your projects to:

Newsletter@DFMachineSpecialties.com

Things to include:

-

Photos of your project

-

What did you make?

-

How did you make it?

-

Which D/F products did you use?

Project submissions will be put in a drawing for a chance to win a $50 Gift Card to your local Best Buy Consumer Electronics Store.

|

|

Words from the Editor

Greetings from D/F!

Thank you for reading our High Current News e-newsletter. Please share this issue with a friend and send us your comments.

Enjoy!

Best Regards,

Dave Judd, Editor

D/F Machine Specialties, Inc.

|

|

In This Issue

-

The Advantage of Preheat

-

Sneezer Anti-Spatter System

-

TIG Stainless Repair Tips

-

Got Projects? Submit to WIN!

-

New Products

-

D/F March Madness Giveaway

|

New Products - Tandem Wire Torch

The D/F Machine Specialties specially designed high amp MIG Tandem welding torch is a critical component of the Tandem welding system, engineered with specific spacing and alignment of two contact tips to achieve proper arc control. The torch is typically rated in the 600-1300 amp range.

-

High Weld Metal Deposition Rate

-

Wide Range of Torch Sizes and Tip Spacing

-

Lowers Production Costs & Increases Productivity

Read More

|

D/F Giveaway

Pick your teams for the showdown in Houston!

Tell us by April 1st, 2011 who will be the winner of the 2011 NCAA Division 1 Men's Basketball Championship on April 4th. Correct answers will be put in a drawing for a chance to win a $50 Gift Card to your local Best Buy Consumer Electronics Store.

Email us your answer!

Congratulations to Brian Dobben of Ellison Technologies Automation for winning the previous issue's giveaway!

|

Your Downloads

Did you know you can download all of D/F's Catalogs, Forms and Instruction Manuals at D/F's Online Download Center?

|

Contact D/F

Product Info: 1-507-625-6200

Fax: 1-507-625-6203

Online: Contact D/F

D/F Machine Specialties, Inc.

1750 Howard Drive

North Mankato, MN 56003

|

|

Follow D/F

You can interact with D/F on Facebook, MySpace, Twitter, Flickr, and YouTube. Sign up to become a Fan on our Facebook Fan Page, become our friend on MySpace, follow us on Twitter, check out high quality photos of our products on Flickr, and see our latest videos on YouTube!

|

|