|

Here is your most recent issue of High Current News. It's packed full of information to keep you updated with the latest MIG & TIG news, product information and updates from D/F MACHINE SPECIALTIES.

D/F is a world leader in the design, development, and manufacture of MIG & TIG welding products, consumables & accessories.

|

|

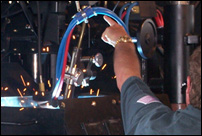

Fixed Automation Welding - When and Why to Use It

Fixed automation generally refers to a setup with machines performing more dedicated movements on repetitive weld joints. The machine can be adaptable to a wide variety of situations, but its operation is usually fixed to perform a basic geometric movement. Fixed automation generally refers to a setup with machines performing more dedicated movements on repetitive weld joints. The machine can be adaptable to a wide variety of situations, but its operation is usually fixed to perform a basic geometric movement.

When performing higher volume repeatable applications, a fixed automation setup would be ideal to achieve higher production at a lower cost. There will be minimum interaction and down time with the fixed machine due to replacement of consumables and changing of parameters.

Parts such as cylinders, pulleys, hubs, tank fittings, exhaust systems, frames, brackets and plates (including many more) can be good candidates for fixed automation welding. When these parts require full circumfrential welds, straight-line continuous or skip welds, or multiple GMAW spot welds, a fixed solution would prove most effective.

Fixed automation cells can produce two or more welds at the same time. For example, when welding two flanges onto either side of a pipe, both welds could be made simultaneously when having two weld heads, and thus cutting the welding time in half, and moreover saving money.

In the end, choosing a fixed automation system is about your return on investment. With relatively high payback on a low budget welding higher production runs with similar parts, a fixed automation system would be the right choice.

Check out D/F's New Water-Cooled-to-the-Tip Automated Machine Torches. This torch recently ran 75,000 inches of 3/32" AL wire on one tip under extreme conditions. Check out D/F's New Water-Cooled-to-the-Tip Automated Machine Torches. This torch recently ran 75,000 inches of 3/32" AL wire on one tip under extreme conditions.

Check out D/F's Automatic MIG Torches

|

|

D/F Water-Cooled Gasless Overlay Machine Torch

The Open-Arc Water-Cooled Gasless Overlay Cladding Machine Torch is recommended for open-arc mechanized cladding applications where production demands the maximum durability and quality for multi-surfacing and rebuilding applications. The Open-Arc Water-Cooled Gasless Overlay Cladding Machine Torch is recommended for open-arc mechanized cladding applications where production demands the maximum durability and quality for multi-surfacing and rebuilding applications.

This torch is ideal for single-head machines or multiple-head machines used with hardfacing and pipe forming applications.

The Open-Arc Machine Barrel is primarily for hard/cored, metal cored, & flux cored wire diameters 7/64" & 1/8" (2.8mm & 3.2mm).

-

Greatly Reduces Maintenance and Down Time

-

Withstands 700 Preheat & 750 Amps Continuous Duty

-

Torch Longevity - Years vs. Months

Learn More About the D/F Water-Cooled Gasless Overlay Machine Torch

|

|

D/F Welding Tips & Tricks - Troubleshooting Consumables

Effectively troubleshooting issues with consumables can greatly reduce consumable costs. Here are some tips for successful finding and solving certain issues. Effectively troubleshooting issues with consumables can greatly reduce consumable costs. Here are some tips for successful finding and solving certain issues.

-

Contact tip burnback: wrong parameters such as tip recess (the tip gets too close to the weld pool, equipment malfunction such as erratic wire feed (tip in correct position).

-

Higher quality consumables will provide better shielding, less porosity, more stable arc, and longer lasting tips and gas cups.

-

Choose correct equipment: for heavy duty welding, a gas cup with too thin a wall and too narrow a bore will not allow adequate gas coverage. A gas cup with too thick a wall and too wide a bore will create too much gas coverage for light duty welding.

-

Liners are another consumable to be considered. Wire kinks and 'bird-nesting' can occur if the liner I.D. is too wide. Obstructions or kinks in the liner itself can lead to erratic wire feed.

There is no one true way to prevent some troubleshooting. The best approach to reducing downtime and costs caused by consumables is to carefully choose your welding consumables, and be sure to set up regular maintenance schedules for your welding equipment.

Check out D/F's Consumables  . .

|

|

Got Projects? Submit Them to WIN!

We want to see how our equipment helps brings out the best of your creativity, skill, or whatever else helps you with your welding projects.

Submit your projects to:

Newsletter@DFMachineSpecialties.com

Things to include:

-

Photos of your project

-

What did you make?

-

How did you make it?

-

Which D/F products did you use?

Project submissions will be put in a drawing for a chance to Win A Gift Card to your local Best Buy Consumer Electronics Store.

|

|

Words from the Editor

Greetings from D/F!

Thank you for reading our High Current News e-newsletter. Please share this issue with a friend and send us your comments.

Enjoy!

Best Regards,

Dave Judd, Editor

D/F Machine Specialties, Inc.

|

|

In This Issue

-

Fixed Automation Welding

-

W/C Gasless Overlay Torch

-

Troubleshoot Consumables

-

Got Projects? Submit to WIN!

-

New Products

-

D/F NBA Finals Giveaway

|

New Products - Robotic W/C-to-the-Tip Barrels

The fully Water-Cooled-to-the-Tip Robotic MIG Standard and Series-A Machine Torches are ideal for welding at currents up to 850 amps and large diameter wires. Very similar in design to the Linde/ESAB ST-12 but with improvements and new features, and proven to be a superior replacement alternative for the Lincoln Electric K148A & K148B, the D/F Machine Water-Cooled-to-the-Tip Torch assemblies are designed to provide long trouble-free service. With the various models available, a contact assembly selection may be made to suit individual torch head requirements.

-

Water-Cooled Inner Body to the Tip

-

Heavy Duty & Long Lasting Construction

-

Small Convenient Frontal Area

Read More

|

D/F NBA Finals Giveaway

The Finals are approaching!

Tell us who will win the 2011 NBA Finals Series this coming June. Correct answers will be put in a drawing for a chance to Win A Gift Card to your local Best Buy Consumer Electronics Store. Please submit your answers no later than May 31st.

Email us your answer!

|

Your Downloads

Did you know you can download all of D/F's Catalogs, Forms and Instruction Manuals at D/F's Online Download Center?

|

Contact D/F

Product Info: 1-507-625-6200

Fax: 1-507-625-6203

Online: Contact D/F

D/F Machine Specialties, Inc.

1750 Howard Drive

North Mankato, MN 56003

|

|

Follow D/F

You can interact with D/F on Facebook, MySpace, Twitter, Flickr, and YouTube. Sign up to become a Fan on our Facebook Fan Page, become our friend on MySpace, follow us on Twitter, check out high quality photos of our products on Flickr, and see our latest videos on YouTube!

|

|