D/F Water-Cooled 650 Amp MIG Pistol Grip Gun

Standard Pistol Gun (7/16"-3/4" Gas Cup ID)

D/F Water-Cooled 650 Amp MIG Pistol Grip Gun

Series A High Capacity Pistol Gun

(11/16"-1" Gas Cup ID)

Drawings Accessories More Info

Overview

With more than 44 years of aluminum and steel trailer welding, D/F Machine Specialties Water-Cooled Semi Automatic MIG 650 Amp Pistol Grip Welding Gun Model NC-21/HT-21 has been push welding aluminum trailers.

The D/F water-cooled MIG semi-automatic 650 amp pistol grip welding gun offers a design with complete interchangeability of nozzle lengths for manual MIG welding of aluminum and stainless steel, using .030" through 1/8" diameter wire. The torch may be adapted to spot or continuous fusion welding, and is ideal for welding with 3/64" and 1/16" AL & SS wire. The D/F Pistol Grip Gun is a superior alternative to the Miller XR-Pistol-Pro and XR-A, and the MK Products Prince XL® Push-Pull Pistol Grip Gun.

The D/F torch is famous for the fact, that if it is chilled properly, the welder can grab the chrome front water-cooled barrel (not the copper gas nozzle/cup) of the torch with their bare hand and it will be cold to the touch seconds after welding. With the proper chiller, this can be done even after a 4 hour arc time. Make certain the cooling water supply is at least the minimum flow rate of 1 gallon per minute (for each inner body), at 40 psi (80 psi maximum) with a 6 gallon reservoir and a recommended 30,000 BTU/hr cooling capacity. Gun ratings are affected by shielding gas used, arc time, cooling time and inlet water temperature. Water outlet temperature should not exceed 27°C (80°F). The torch’s water out & power cable is not cooled until the coolant has gone through the torch and out the water out & power cable. If water is not flowing through the D/F torch for at least 1 minute prior to striking an arc, when you apply the power and water hits the “hot” water/out & power cable, you will generate steam. Steam can damage the torches internals in seconds causing a leak. It can also blow out the torches water/out & power cable. A flow switch can be installed after the return line ensuring that coolant is present at the return line prior to striking an arc. When High-Deposition GMAW, high current density, high amperages, preheat, or extended periods of arc time are used, a refrigerated liquid chiller with a larger reservoir is required. Precise temperature control maintains the cooling at a constant 13°C (55°F) temperature, thus prolonging the life of the welding equipment and more specifically extending the service life of the gas nozzle and current tip. D/F Machine Specialties does not manufacture or sell chillers, we only recommend them. Click here to see our recommended chillers.

Each D/F Machine Specialties welding gun is fully assembled and ready to install. In order to make the installation complete, the code number, wire size, wire feeder make/model (Lincoln wire feeders, Miller wire feeders, Tweco wire feeders, ESAB wire feeders, & EURO Quick Disconnect wire feeders), and inlet (as needed) must be specified when ordering. If special welding tools or accessories other than those listed previously are required, please consult with the factory. Get the right feeder adapter connection to fit your MIG wire feeder.

If you like all of the heavy-duty, robust design features and low costs of the D/F Water-Cooled Pistol Grip Welding Gun, but always wish that you had a curved gun, please check out our NCC/HTC, Mighty MIG, and HTC-E/HTCE-A 55 Degree Water-Cooled Semi-Automatic Hand Guns.

Features

- Water-Cooled Inner Body & Nozzle

- NC-21S - Optional Directly Cooled Spot Nozzle

- Small Frontal Area for Hard-to-Reach Locations

- Nozzle Length may be Extended by Applying Either of Three (3) Different-Length W/C Nozzle Assemblies

- Optional Curved Nozzle Kit

- Optional Heat Shield

Model Explanation

- NC-21 - Normal Duty Pistol, Water-Cooled Collet Action (Slip-in Current Tip)

- HT-21 - Heavy Duty Pistol, Water-Cooled Threaded Current Tip

- NC-21-A - Normal Duty, W/C Collet Action (Slip-In Tip) - High Capacity (Series A)

- HT-21-A - Heavy Duty, W/C Threaded Tip (CuCrZr) - High Capacity (Series A)

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) |

COOLING REQUIRED |

RECOMMENDED WIRE DIA. RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|---|

| NC-21 | 650 amps @ 100% Duty Cycle |

2.5 lbs | 5 pints/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

163WP |

| HT-21 | 650 amps @ 100% Duty Cycle |

2.5 lbs | 5 pints/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

163WP |

| HT-21-A, HT-21-A |

650 amps @ 100% Duty Cycle |

2.5 lbs | 5 pints/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

161WP |

Barrel Dimensions

| MODEL | Length w/ 3" Nozzle | Length w/ 4" Nozzle | Length w/ 5" Nozzle | Diameter of Barrel Housing | Diameter of W/C Nozzle |

|---|---|---|---|---|---|

| NC-21/HT-21 | 9.25" | 10.25" | 11.25" | 1.625" | 1.125" |

| NC-21-A/HT-21-A | 9.25" | 10.25" | 11.25" | 1.625" | 1.445" |

Ordering Information

For Hard & Cored Wire

| DESCRIPTION | CODE NO. | ||

|---|---|---|---|

| Model NC (Slip-in Tips) |

10 Ft. Casing |

12 Ft. Casing |

15 Ft. Casing |

| Short 3" W/C Nozzle | 11231 | 11236 | 11251 |

| Inter. 4" W/C Nozzle | 11233 | 11237 | 11252 |

| Long 5" W/C Nozzle | 11234 | 11238 | 11253 |

| Model HT (Threaded Tips) |

10 Ft. Casing |

12 Ft. Casing |

15 Ft. Casing |

| Short 3" W/C Nozzle | 11261 | 11266 | 11271 |

| Inter. 4" W/C Nozzle | 11262 | 11267 | 11272 |

| Long 5" W/C Nozzle | 11263 | 11268 | 11273 |

For Aluminum Wire

| DESCRIPTION | CODE NO. | ||

|---|---|---|---|

| Model NC (Slip-in Tips) |

10 Ft. Casing |

12 Ft. Casing |

15 Ft. Casing |

| Inter. 4" W/C Nozzle | 11286 | 11287 | 11288 |

Series A - High Capacity

| DESCRIPTION | CODE NO. | ||

|---|---|---|---|

| Model NC-A (Slip-in Tips) |

10 Ft. Casing |

12 Ft. Casing |

15 Ft. Casing |

| Short A3" W/C Nozzle | 11344 | 11347 | 11350 |

| Inter. A4" W/C Nozzle | 11345 11305 |

11348 11306 |

11351 11307 |

| Model HT-A (Threaded Tips) |

10 Ft. Casing |

12 Ft. Casing |

15 Ft. Casing |

| Short A3" W/C Nozzle | 11353 | 11356 | 11359 |

| Inter. A4" W/C Nozzle | 11354 | 11357 | 11360 |

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| NC-21/HT-21 | 163WP |

| NC-21-A/HT-21-A (Series A High Capacity) |

161WP |

CAD Files & Drawings

| TORCH MODELS | CAD FILE | PDF DRAWING |

|---|---|---|

| NC-21/HT-21 | NC-21/HT-21 | NC-21/HT-21 |

| NC-21/HT-21 with Heat Shield | NC-21/HT-21 | NC-21/HT-21 |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Torch Connection Options | |

| W/C Pistol Gun One-Sheet |

Utility Station #45196

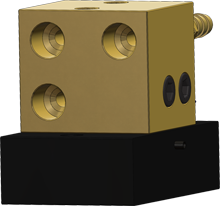

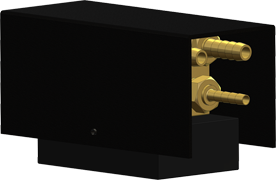

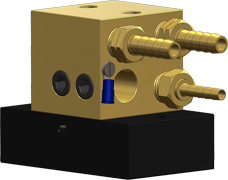

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.

Heat Shield #14525

Naturally, manufacturers and fabricators have taken a number of measures over the years to combat heat exposure. While intense heat can certainly be irritating for the welder, the impact is more than an issue of comfort. There are significant safety, liability and productivity considerations as well. Reflective heat when welding is very hot. The reflective heat and weld puddle that is present when MIG welding aluminum is even hotter. The D/F Machine Specialties Heat Shield for the MIG Pistol gun directs the heat away from the hands, significantly reducing temperatures. Unlike other heat shields, the D/F heat shield has a dual wall design. The outside wall reflects the heat and provides and insulator from the inside wall. It also protects the hands and the torch from weld spatter. What’s more, the heat shield is comfortable and lightweight, so it can be mounted on a D/F Pistol gun without sacrificing performance. You won’t even notice the heat shield is there.

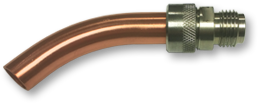

Curved Nozzle Kit #13925

The optional Curved Nozzle Kit is available with a 55° nozzle that can be attached in place of the regular gas cup. The curved nozzle can be turned in any direction from the front of the torch. The kit is available with bent current tips accommodating a wire diameter range of .035"-1/16" for hard wire, and 3/64"-1/16" for aluminum wire. See the D/F MIG Welding Contact Tips page for more information on the bent current tips. Download the product one sheet for more information on the Curved Nozzle Kit.

More Info

Remember the great Airco Aircomatic Model AH50-B Welding Gun that was used exclusively for gas metal arc (MIG) spot welding of aluminum and hard wires? Very similar in design to the Linde ST-5 and ESAB ST-21 (part no. 995950) welding guns but with improvements and new features, and proven to be a superior replacement alternative, the D/F water-cooled handheld pistol grip MIG push gun is a rugged all purpose, water-cooled, manual MIG welding torch designed to operate at welding currents up to 600 amperes continuous duty using all types of shielding gases. The torch utilizes a pistol grip design for convenient start-stop welding control and easy handling, and its in-line type construction allows all service lines to enter through the torch barrel. Like the ESAB ST-21, the D/F Pistol Gun is easily connected to the ESAB MIG-35 wire feeder. The DF Pistol is also intended for use with all wire feeders that have provision for water cooling and will handle all types of welding wire from .035" diameter through 1/8" diameter flux cored wire, and 3/64" AL through 3/32" Aluminum wire.

To provide maximum resistance to the abuses of day to day service, the pistol grip torch is of heavy duty construction with all metal parts well insulated from current carrying members. The in-line body and pistol grip handle allow the D/F Pistol to be used in a variety of applications with easy maneuverability and comfortable operation. To facilitate maneuverability, all service lines are internally connected to the torch body and exit from the rear of the torch barrel. The torch can use either threaded contact tips or slip-in contact tubes which are secured with a collet nut supplied with the torch. The contact tip can be quickly and easily replaced by unscrewing the metal nozzle and collet nut, and removing the tip. Six water-cooled metal nozzles with different lengths and different I.D./O.D. are available for use with the D/F Pistol for continuous fusion welding and for spot welding applications. The water-cooling requirements for the D/F Pistol are described below.

Naturally, manufacturers and fabricators have taken a number of measures over the years to combat heat exposure. While intense heat can certainly be irritating for the welder, the impact is more than an issue of comfort. There are significant safety, liability and productivity considerations as well. Reflective heat when welding is very hot. The reflective heat and weld puddle that is present when MIG welding aluminum is even hotter. The D/F Machine Specialties Heat Shield for the MIG Pistol gun directs the heat away from the hands, significantly reducing temperatures. Unlike other heat shields, the D/F heat shield has a dual wall design. The outside wall reflects the heat and provides and insulator from the inside wall. It also protects the hands and the torch from weld spatter. What’s more, the heat shield is comfortable and lightweight, so it can be mounted on a D/F Pistol gun without sacrificing performance. You won’t even notice the heat shield is there.

Comparing Push Guns, Push-Pull Guns, and Spool Guns

Push Gun Benefits

Feeding aluminum wire through a push only system is very advantageous. The D/F Water-Cooled Pistol Gun easily connects to a Millermatic 350P and XR-AlumaFeed, and is a superior alternative to the Miller XR-Pistol-Pro and XR-A, and the MK Products Prince XL® Push-Pull Pistol Grip Gun. The D/F Pistol is inexpensive unlike the push-pull MIG torches and spool guns on the market today. Push-pull torches are also very fragile, difficult to maintain, and have more parts. A push gun requires u-groove drive rolls to provide more surface contact with the wire, a nylon liner, and adequate drive-roll pressure. With the use of the D/F steel reinforced casing supporting the liner, the D/F Pistol Gun can push 3/64", 1/16", and 3/32" aluminum wire up to 15 feet. Because the D/F Pistol Gun can hook up to any manufacturer's wire feeder and power source, large spools of wire can be used reducing expenses, down time, and wear and tear on the torch by the changing of spools, as in a spool gun. A spool gun needs to have the roll changed after every pound of wire is used, compared with the 8 or 15 lb spool on a push-pull system. In tight spaces, the spool may limit access, requiring the operator to use a longer stickout. If the operator is using several pounds of aluminum per day, the few minutes need to change spools can add up. Also, the chance of burnback exists when the end of a spool is reached, so many operators stop when a few turns are left on the spool.

Spool Gun Limitations

Because a spool gun is larger than a push gun, it can sometimes be difficult to get close access to the weld. Also, a spool gun can only hold a 1 pound spool of aluminum wire electrode, so changeovers are frequent. In addition, these small spools typically are not the most economical way to purchase wire.

Push-Pull Gun Limitations

Typically, the greatest disadvantage of a push-pull system is that it requires the most number of components and is the most expensive. Push-pull guns are also very fragile and do not last as long.

Push Welding vs. Push-Pull Welding

A push gun also has advantages over a push-pull gun for many reasons. Typically, the greatest disadvantage of moving wire over long distances with a push-pull system is that it requires the most number of components and is the most expensive. It is very easy to mount a D/F Pistol Gun on a boom system to take all of the weight off of the gun. By mounting the wire feeder and power source on a 4-wheel cart, you can now travel great distances very easily. Push-pull guns are also very fragile and do not last as long (months vs. years). Push-pull guns are 2-3 times more expensive than the D/F Pistol. They only last up to 9 months on average, and you either have to replace the torch or rebuild by installing a new motor costing as much as $400-plus. Lastly but most importantly, because the D/F Pistol uses a 4" contact tip that is recessed in the water-cooling, not only is the arc stability increased, the tip life is increased 7-1, and there is built-in wire straightening. If the operator is using several pounds of aluminum per day, the few minutes need to change spools or replace motors can add up.

Pushing Aluminum Wire

Feeding aluminum wire through a push only system is very advantageous. Because push-only guns like D/F Pistol Gun can hook up to any manufacturer's wire feeder and power source, large 300 lb spools of wire can be used reducing expenses, down time, and wear and tear on the torch by the changing of spools as in a spool gun. A spool gun needs to have the roll changed after every pound of wire is used, compared to the large size spools used in a D/F Pistol Gun. Also, the chance of burn-back exists when the end of a spool is reached, so many operators stop when a few turns are left on the spool.

Trailer Manufacturing

When manufacturing high quality aluminum trailers, it is important to consider longevity and strength of the weld joints. With aluminum in particular, it is somewhat of a fine-tune process to get a weld that will penetrate correctly with slightly higher heat and slightly lower travel speed. Also, choosing the correct wire size is crucial to an optimally strong aluminum weld. Since the D/F Water-Cooled Pistol Gun can handle a wide range of wires, and can hook up to any power source and wire feeder to accept any necessary welding parameters, it is a superior choice for manual MIG aluminum welding and trailer manufacturing.